Amy Sprague

January 26, 2026

A&A capstone team's smart strake system dynamically adapts to flight conditions, showing a promising drag reduction in the wind tunnel with respect to passive strakes. This approach has the potential to save airlines hundreds of kilograms of fuel per flight.

The fin-like passive strakes on the engines boost lift and avoid stall on takeoff and landing, but increase drag during cruise.

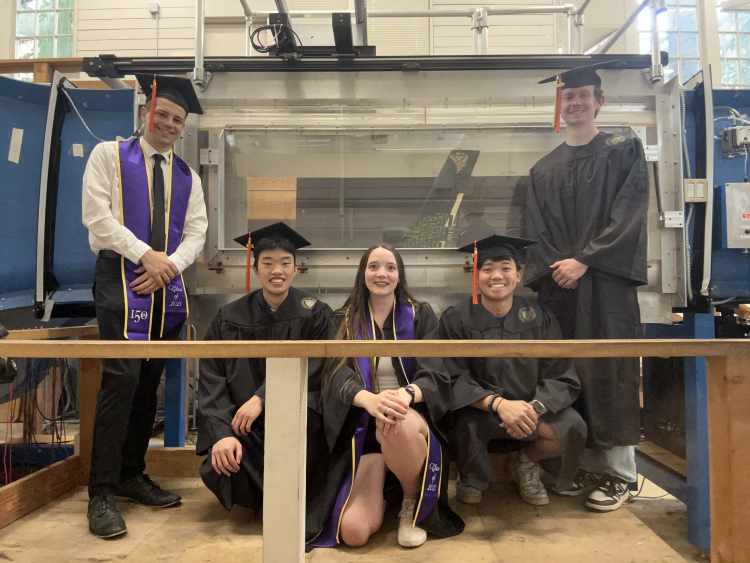

Cade Homfeldt, Aaron Wu, Fiona Spitzley, Matthew Saludares and Hugh Carbrey doing final tests in the 3X3 wind tunnel before the department graduation ceremony.

For decades, aircraft have carried a fundamental compromise between their engines and wing flow interactions by using strakes. These are small fins attached at the sides of engine nacelles that generate helpful vortices during takeoff and landing that boost lift and avoid stall, but create unwanted drag during cruise flight. Now, seven A&A undergraduates have advanced a solution that improves this trade-off, achieving up to 33% drag reduction, on the limited tested conditions, during cruise while maintaining critical safety benefits at high angles of attack.

Giovanni Nino, Affiliate Associate Professor

The team—Hugh Carbrey, Cade Homfeldt, Alexander Maldonado, Matthew Saludares, Paul Snyder, Fiona Spitzley, and Aaron Wu—worked under the mentorship of Giovanni Nino, an Affiliate Associate Professor with 18 years of R&D experience and over 50 patents, Professor Robert Breidenthal of A&A’s Vortex Transport Lab, and Professor Alvar Saenz Otero, lead of our capstone design program. They validated the concept of an “active strake” that uses controlled air injection to dynamically adjust vortex flow based on the angle of attack to reduce drag during cruise flight.

Building on the lab's previous small-scale research in vortex control by master’s students Tobias Wittig and Lucas Weber, the capstone team scaled the concept to a half-wing model with an engine nacelle and strake. "The previous research proved concept viability on just a strake," explains Fiona Spitzley, now an A&A master’s student, who handled systems engineering for the team. "We went a step farther by attaching it to a model that was representative of an actual airplane.”

From paper concept to wind tunnel

The half-wing model undergoes testing in A&A's 3x3 low-speed wind tunnel. Inspired by the Boeing 737-800, the model features a smart strake with three injection ports. The team tested configurations at 5 and 10-degree inclination angles to optimize vortex control.

The project began with "Iteration Zero"—a paper model assembled at the University Village Starbucks on a Friday afternoon. "We had pieces of paper, and we just cut out the first size of our elements," recalls Spitzley. "We looked at that and said, 'Whoa, that's really big.' So we knew to scale down the next version."

That paper model, which didn't survive the day, launched an intensive development process that produced three iterative models for the wind tunnel. Each version refined the design—smoothing the nacelle, thinning the pylon, and eventually adding channels to keep air hoses flush with the wing surface. Spitzley managed much of the 3D printing in Maple Hall’s Dabble Lab, where printer bed size constraints meant dividing the wing into sections that were later assembled with fiberglass reinforcement.

The making of the “Iteration Zero” paper model with Cade Homfeldt, Hugh Carbrey and Alexander Maldonado bonding the strake on an engine nacelle.

Hugh Carbrey, the team's structural analyst and also now an A&A master’s student, managed the interface with the wind tunnel. "I was in charge of making sure that anything we put in the wind tunnel didn't fail. If we broke the wind tunnel on our first test, our capstone would be a failure because we couldn't get any data. And we'd be the most hated group on campus."

"This project demonstrates the power of combining rapid prototyping with rigorous testing," notes Nino. "In just one academic quarter, these students went from paper mockup to wind tunnel validation, producing results that challenge decades of accepted aircraft design."

The strake tradeoff

Strakes boost lift and reduce stall speed during high angles of attack during takeoff and landing, adding a great safety feature. But aircraft spend most of their time during cruise flight when strakes increase drag, forcing airlines to burn extra fuel for the majority of each flight to maintain a safety feature needed only during takeoff and landing.

Breakthrough results and the 'aha' moment

Three model iterations: Each iteration incorporated lessons learned, culminating in a sophisticated model (right) with CNC-milled aluminum strake, 3d printed body sections, carbon steel spars, and a fiberglass-epoxy composite skin.

The smart strake translates directly to fuel savings and a reduction in carbon emissions. A 10% reduction in drag typically yields a 13% fuel savings, meaning the team's optimized 33% drag reduction could save approximately 650 kilograms of fuel on a typical narrow-body aircraft flying from Seattle to Los Angeles. Also, moving from a passive to an active strake showed wing stall was delayed from 17 degrees to 18 degrees.

The system maintains its advantages across various flight conditions. Testing from -4 to 22 degrees angle of attack showed consistent improvements, with drag reductions exceeding 10% throughout the critical cruise range.

The team's "aha" moment came after their third wind tunnel test during finals week. "We processed all the data at once," Carbrey recalls. "You go from having just this raw data that doesn't really mean anything, and then you get the coefficients at once. Seeing that blowing a little bit of air through this fin changes the aerodynamic capabilities at all was pretty cool."

A close-up of the aluminum strake with three precisely positioned injection ports that deliver air and change the vortex over the wing for a more efficient cruise stage of a flight.

"Suddenly we saw that the difference between the passive configuration and the active configuration was pretty significant," adds Spitzley. "It actually worked!"

Additional testing and refinement is next. The team’s current model increased the relative size of the strake to ensure it was big enough for wind tunnel results and it will be resized on next design iterations. The research continues with current master's student Josh Kruetz testing additional configurations such as flap positions, pneumatic injection, and strake angles building on the capstone team's foundation.

The smart strake concept addresses one of aviation's persistent efficiency challenges as industry faces constant pressure to reduce emissions and operating costs. "The industry has accepted passive strakes as a necessary compromise for 50 years," says Nino. "These students demonstrated a solution that eliminates that compromise while maintaining all the safety benefits at stall."

Testing until the last minute, the team brought their caps and gowns to the wind tunnel for their final tests on graduation day, then gathered for a photo after the ceremony. (L-R Fiona Spitzley, Hugh Carbrey, Paul Snyder, Aaron Wu, Professor Breidenthal, Matthew Saludares, Cade Homfeldt, Alexander Maldonado).

The numbers validate years of theoretical and small-scale work. At a typical cruise angle of attack of 4 degrees, the smart strake tested at a subset of conditions achieved:

33%

reduction in drag coefficient compared to passive strakes

45%

improvement in lift-to-drag ratio

+1°

stall margin increase from 17 degrees to 18 degrees

Go to the sources

Cade Homfeldt presented the team's findings at the AIAA SciTech 2026 conference. Their paper, "Smart Engine Nacelle Strake," details both the aerodynamic principles and practical implementation of their system.

View the team’s video submission to the 2025 Capstone Film Fest, which won the “Best in Show” award.