Bending the constraints of digital fabrication

By: Amy Sprague

January 12, 2026

Top image: The Programmable Matter Lab’s WireBend-kit with (L-R) Assistant Professor Martin Nisser and lab members Carson Taylor (ME), Anthony Guinto (A&A), Riley Schuler (ME) and Josha Paonaskar (A&A).

Photos by Dennis Wise

Assistant Professor Martin Nisser's student research team makes advanced wireframe fabrication accessible, creating recyclable aluminum structures with applications from makerspaces to spacecraft.

When Assistant Professor Martin Nisser and his team of nine undergraduate researchers in the A&A's Programmable Matter Lab looked at the landscape of digital fabrication, they saw a few problems. Commercial wirebending machines cost up to $68,500. Affordable 3D printers create mountains of plastic waste that end up in landfills, and these printers also limit the size of objects they can create.

Their solution is WireBend-kit, a desktop wirebending machine that costs just $293 to build and transforms recyclable aluminum wire into strong, complex 3D structures in minutes rather than hours.

"We wanted to bring a technology that's been locked away in industrial settings to everyone," says Nisser. "But more than that, we wanted to create something that addresses the sustainability crisis in personal fabrication. Every wireframe structure we make can be completely recycled and turned into new objects with virtually no loss of material integrity."

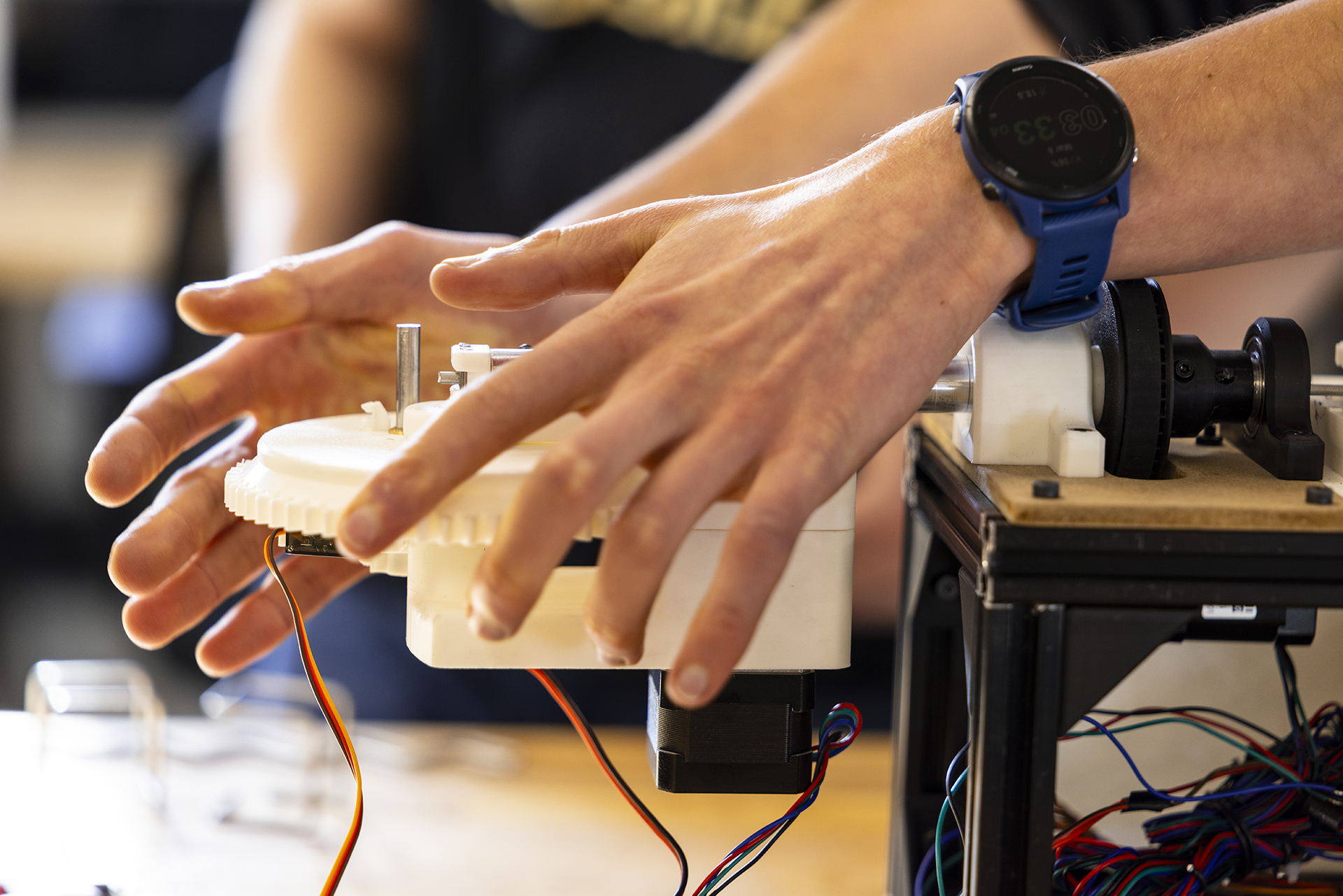

Left: A&A senior Josha Paonaskar and ME senior Riley Schuler work with the design and animation interface of WireBend-kit before fabrication. Top right: Schuler makes a slight adjustment to the bending assembly, which physically deforms the wire. Bottom right: A closeup of a wireframe cube produced in seconds.

Students build faster, smarter, bigger, cheaper

The nine undergraduate students spanning A&A, mechanical engineering, electrical and computer engineering and computer science—Josha Paonaskar, Riley Schuler, Aiden Prevey, Carson Taylor, Anika Tak, Anthony Guinto, Eeshani Shilamkar, and Natarith Cheenaruenthong—tackled everything from mechanical design to software development, creating an end-to-end design and fabrication tool at a fraction of the cost of comparable commercial machines.

Their kit combines a user-controlled design tool that gives creators full authority over their wireframes with sophisticated error-correction software that turns less than a few hundred dollars of hardware into a precision instrument. Users upload a 3D model as a stencil in the team's custom Blender plugin, trace their desired wireframe structure, and watch as the student-developed software checks their design in real-time.

"The software is constantly validating whether what you're designing can actually be made," explains Nisser. "It checks if a continuous path exists for the wire, whether your bend angles are physically possible, and if your segments are long enough. Then it shows you an animation of the entire fabrication process so you can spot any collisions before you commit to making it."

The kit solves two types of errors that plague wirebending: "springback," which is the partial unbending due to the aluminum's elasticity, and "setback," a geometric error where the angle swept by the machine's bending mechanism doesn't match the angle swept by the wire itself.

"Setback hadn’t been modeled outside of sheet metal bending," notes Nisser. "Once we understood and compensated for both errors in our software, we achieved great improvements in feed accuracy and bend angle precision. Now, this machine built with hobby-grade components can produce professional results."

“Students can build this machine themselves, understand every component, and modify it for their needs. We want to create opportunities for other engineers to innovate.”

A comprehensive introduction to the WireBend-kit with a selection of sample shapes the kit can produce.

From shared on Earth to building on-orbit

"By making this completely open source, we're inviting the global maker community to take this technology to places we haven't even imagined yet.”

All designs, software, and documentation will be freely available. The Blender plugin, machine blueprints, and assembly instructions enable anyone, from high school makerspaces to university research labs, to build their own WireBend-kit.

The applications stretch from Earth-based workshops to on-orbit manufacturing, where weight, strength, and sustainability really matter. This application will also benefit from the advantage that the size of the creation is not limited to the size of the printer. The rapid prototyping capabilities accelerate aerospace design cycles as engineers can test structural concepts in minutes and create custom fixtures on demand.

For on-orbit manufacturing, material recycling will be critical without easy re-supply. With aluminum wire that doesn’t degrade, engineers can reshape the wireframes into something new, repeatedly.

"By making this completely open source, we're inviting the global maker community to take this technology to places we haven't even imagined yet," says Nisser. "Every time I see one of our aluminum wireframes next to a pile of failed 3D prints, I'm reminded why this matters."

Go to the source

Faraz Faruqi, Josha Paonaskar, Riley Schuler, Aiden Prevey, Carson Taylor, Anika Tak, Anthony Guinto, Eeshani Shilamkar, Natarith Cheenaruenthong, and Martin Nisser. 2025. WireBend-kit: A Computational Design and Fabrication Toolkit for Wirebending Custom 3D Wireframe Structures. In Proceedings of the ACM Symposium on Computational Fabrication (SCF '25).