August 4, 2025

Alexis Harroun (A&A ‘17) will be first to launch a rotating detonation rocket engine for an orbital flight.

Alexis Harroun

A&A alum Alexis Harroun (A&A '17) is making space industry headlines as her Seattle startup prepares to launch the first U.S. orbital flight of a rotating detonation rocket engine. When Harroun steps into mission control next summer, she'll be watching her company's advanced propulsion technology fire in space for the first time — a moment that will make aerospace history and cap off a journey that began in a UW lab nearly a decade ago.

Harroun's startup with her co-founder Ariana Martinez, Juno Propulsion, is developing satellite thruster technology that could transform spacecraft propulsion systems. The two met as Ph.D. students at Purdue University, where Harroun continued the rotating detonation research that began during her undergraduate research with Professor Carl Knowlen who leads A&A's Detonation Engines Lab.

"I worked with Professor Knowlen for all four years that I was here," Harroun says. "He's been a really good mentor to me in that time. It was really cool to kind of come back and be able to tap into that."

A different kind of engine

Juno’s Ariana Martinez assembling the Juno V1 prototype in A&A’s Detonation Engines Lab.

So what makes rotating detonation rocket engines special? Traditional rocket engines burn fuel in a controlled combustion process. Rotating detonation engines, by contrast, use a continuous wave of detonations that spin around the engine at incredible speeds — controlled explosions that are far more efficient than conventional burning.

"We are developing propulsion systems that use this rotating detonation engine technology as the key differentiator," Harroun explains. The result is a thruster that could dramatically reduce the fuel needed for satellite maneuvers, making space missions more affordable and opening up new possibilities for exploration.

Her thruster uses non-toxic propellants — ethane and nitrous oxide — that are safer to handle than traditional toxic rocket fuels and can be stored as self-pressurizing liquids at room temperature. Using these propellants eliminates the need for complex pressurization systems, making the overall propulsion system 30% smaller in volume, 15% lighter in mass, and requiring 40% less power than conventional solutions.

While Japan's space agency flew a rotating detonation engine on a suborbital flight in 2021, Juno's mission will be the first to test the technology in orbit — a much more demanding environment where the engine will need to operate for months, not minutes.

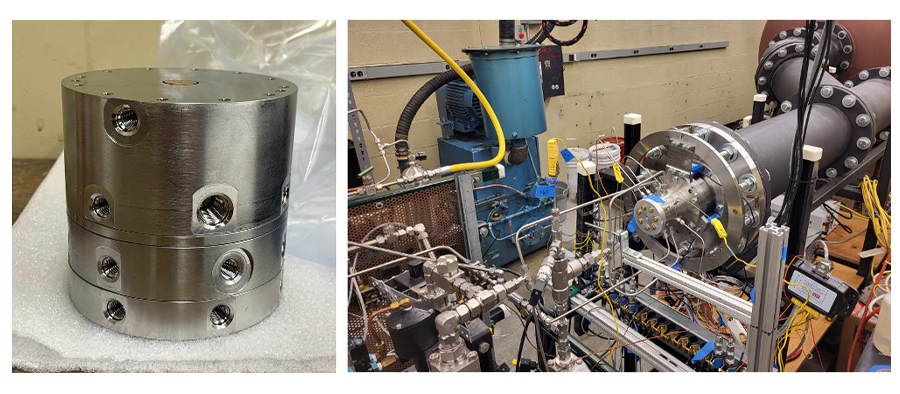

Juno’s thruster prototype (left) that is now installed in the rotating detonation engine experimental setup (right).

“Alexis's passion for this technology grew out of our lab work together, and now we're collaborating to turn that early research into something that will fly in space.”

Mission to orbit

Next summer, Juno's propulsion system will hitch a ride to space on one of NASA's rideshare missions. Once in orbit — likely a sun-synchronous polar orbit typical for such flights — the real work begins.

The satellite will circle Earth 14 times per day, but Juno will only be able to communicate with it three to six times daily when it passes over ground stations. During those brief windows, Harroun and her team will send commands to test different aspects of their propulsion system.

"It's definitely going to be an iterative process where we look at data, see if it makes sense, and then either say, 'Hey, you're on track, continue your mission objective,' or maybe we program something different," she explains.

Building the future

The mission timeline is aggressive — Juno needs to deliver their payload by March 2026, just eight months away. To meet that deadline, Harroun is rapidly scaling her two-person company. They're moving into a 3,000-square-foot facility in Tukwila where they can fabricate, assemble, and test their systems. The plan is to hire two to three new engineers in the coming months, including specialists in fluid systems and mechanical systems.

The technology promises significant advantages: satellites using Juno's propulsion system could see their payload capacity increase by 50%, their operational lifespan double, and their speed to target orbit increase dramatically. For the growing satellite industry — projected to reach $1 trillion by 2030 — these improvements could translate to millions in cost savings per mission.

Collaborations from lab to launchpad

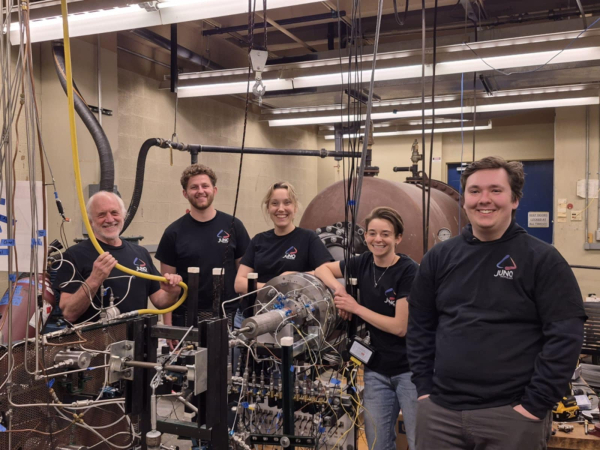

Professor Carl Knowlen), Juno intern Ben Cabot, Alexis Harroun, Ariana Martinez and A&A graduate student Ben Fetters.

The path from university lab to space mission has involved partnerships at every level. NASA recently awarded Juno Propulsion $500,000 through its Tech Leap prize to demonstrate their propulsion system in space — validation of technology that Harroun and Knowlen have been developing together through funding from Washington state's Joint Center for Aerospace Technology Innovation (JCATI). This builds upon a previous $275,000 National Science Foundation seed fund grant (with 30% going to the UW).

"Being able to work with the UW was really big for us," she says. The JCATI grant has been "a big pivotal moment for the company to have external research dollars."

"What's exciting is seeing this come full circle," Knowlen explains. "Alexis's passion for this technology grew out of our lab work together, and now we're collaborating to turn that early research into something that will fly in space. Our master’s students Ben Fetters, Kai Laslett-Vigil and Andrew Takacs are part of that journey, gaining invaluable hands-on experience you can't get anywhere else."

Beyond the horizon

For Harroun, the mission represents more than just a business milestone. It's proof that the collaborative spirit between university researchers and entrepreneurs can tackle some of the biggest challenges in space exploration.

"We're going to be up there for probably a couple months at least for this demo mission," she says, anticipating the moment when her rotating detonation engine fires in the vacuum of space for the first time.

When that happens, it won't just be a victory for Juno Propulsion — it'll be a testament to the power of mentorship, partnership, and the kind of boundless thinking that turns undergraduate research projects into aerospace history.