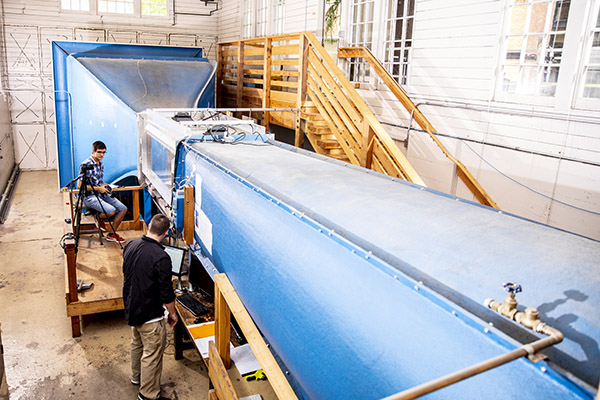

The 3x3 Low Speed Wind Tunnel is an open-loop facility capable of 135mph (60m/s) flows. The wind tunnel is heavily used for undergraduate labs and projects in the winter and spring quarters and for research the remainder of the year.

Capabilities

- Wind speeds: 15-60 m/s (34-135 mph)

- Test section: 3’x3’x8’

- 9:1 contraction ratio

Specifications

Sting balance

Balance limits

The balance will be permanently damaged if it experiences forces greater than or equal to:

| Normal, side force | Axial (Drag) | Roll |

|---|---|---|

| 200 lbf | 50 lbf | 60 lbf-in |

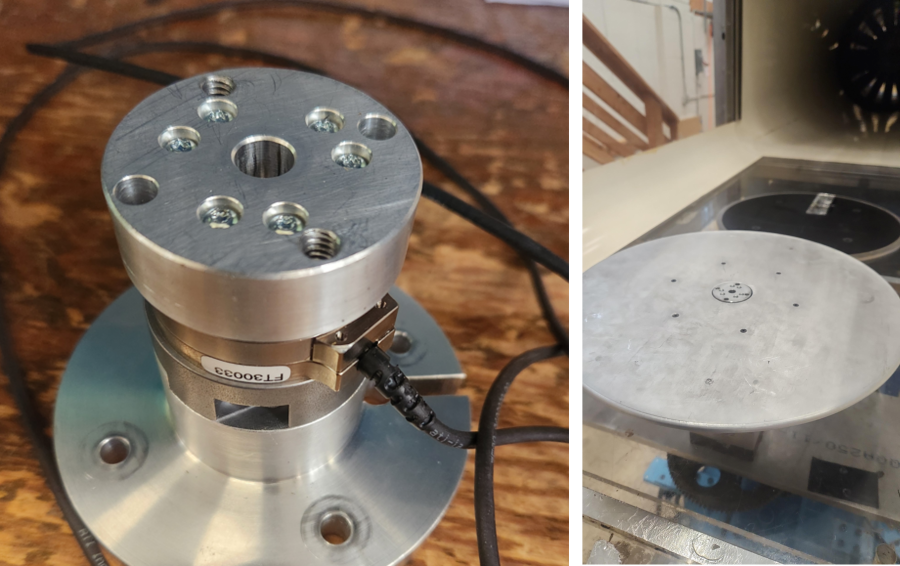

Half-body balance

The Half-body balance sits on the floor of the test section within the turntable.

Balance limits

The balance will be permanently damaged if it experiences forces greater than or equal to:

| Fx, Fy | Fz | Tx, Ty | Tz |

|---|---|---|---|

| 60 lbf | 120 lbf | 80 lbf-in | 80 lbf-in |

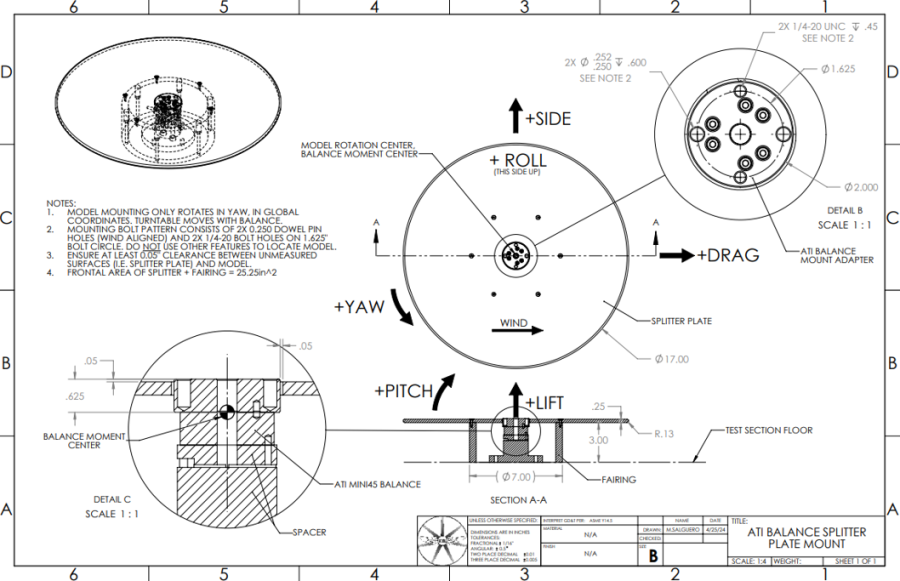

Technical drawing of an ATI balance splitter plate mount showing top, side, and sectional views with labeled axes for roll, yaw, pitch, drag, and lift, plus detailed assembly notes.

Request tunnel time

Read the guidelines and requirements to ensure a smooth reservation and testing experience.

How to submit a requestAbout the tunnel

In early 1917, William E. Boeing hired two University of Washington mechanical engineering students, Clairmont L. Egtvedt and Philip G. Johnson, for his budding aeronautics company. Though Egtvedt and Johnson eventually became two of the most influential figures in aviation history, Boeing quickly saw a need for a formal program in aeronautics.

Boeing realized that he needed not only trained aeronautical engineers, but also a facility to test new airplanes. He donated a wind tunnel to the University of Washington as the first wind tunnel in the Northwest on the condition that the UW develop an aeronautics curriculum. Design and construction of the new wind tunnel started in late 1917.

The current 3x3 Low Speed Wind Tunnel is housed in the same historic building as Boeing’s original wind tunnel, long since replaced.

Read more about The Boeing Aerodynamical Chamber and its Impact on Aeronautics Education at the University of Washington.