Amy Sprague

April 5, 2024

Graduate student assistants make mini wind tunnels for more hands-on experience in Junior Lab.

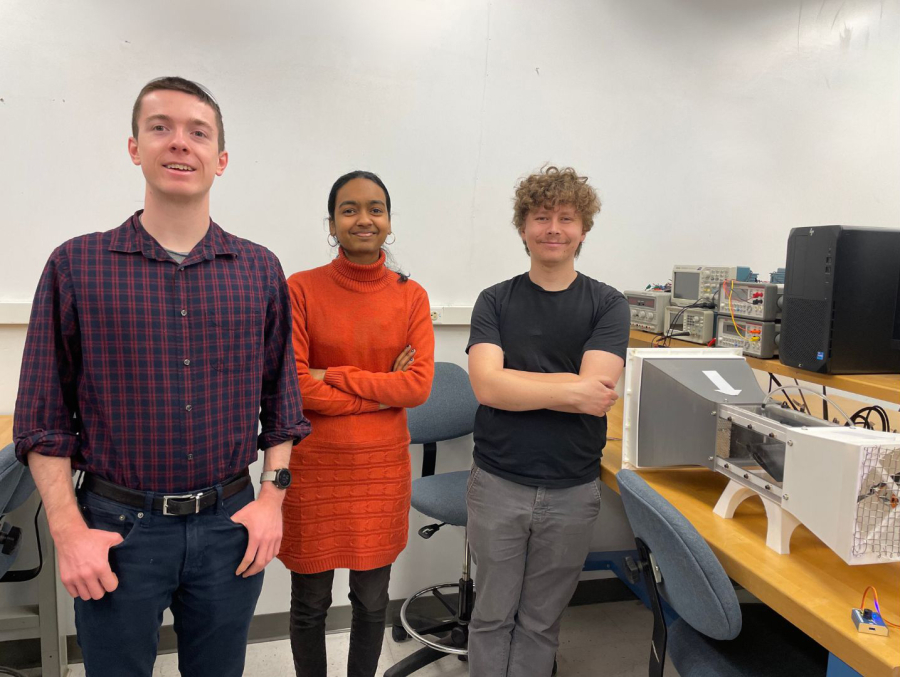

Colin Baxter, Asha Rashmi and Bennett Diamond with one of the mini wind tunnels they created for Junior Lab.

A&A’s Junior Lab used to have units in our 3X3 wind tunnel. Students measured drag on bluff bodies, calculated aerodynamic characteristics of airfoils, and found stall angles through flow visualization with tufts. But these units were not hands-on for all at the same time. This year, our graduate student assistants Colin Baxter, Asha Rashmi and Bennett Diamond manufactured mini wind tunnels so that small teams in Junior Lab could gain more hands-on experience with various experiments over the three week unit.

Students carried out all of the previous experiments, though the tufts were swapped out with a smoke machine for the flow visualization, and students now had the opportunity to 3D-print a custom airfoil and measure its characteristics.

Baxter, Rashmi and Diamond and Assistant Teaching Professor Alvar Saenz Otero, one of the Junior Lab instructors, answered our biggest questions about launching this new approach.

Flow visualization using a smoke machine over a 3D-printed airfoil.

Where did this concept of making mini wind tunnels come from?

Colin Baxter: A 2023 junior capstone team (the “Benchwarmers”) designed and built a mini wind tunnel in less than an academic quarter. It was a phenomenal student project and inspired the instructors. Rather than multiple teams getting limited time with the 3x3 wind tunnel, these small tabletop wind tunnels would allow for each team to get not only more time, but a more hands-on experience with the experiments. Bennett, Asha and I, as the department Graduate Student Assistants, were tasked with using the capstone project as a starting point to develop robust, high-performing wind tunnels that would adequately serve the junior curriculum.

How did you three make them and what were the biggest challenges?

Asha Rashimi: Most of the components of the wind tunnel have been 3D printed with an acrylic test section. We also 3D printed the test airfoils. First, we created a demo wind tunnel to ensure that we had a working model. We ran into an issue with the fans we had ordered as their speeds were considerably lower when the wind tunnel mesh was placed in front of them. The available pressure sensors were not sensitive enough to record a pressure reading with the lowered man speeds. We remedied this by replacing our fan with a more powerful motor connected to a prop. We also faced issues with fitting all the 3D printed pieces together. Since all the components have their own tolerance, we had to be very precise in our calculations.

What is the advantage of using these mini wind tunnels in Junior Lab?

Bennett Diamond: The advantages come down to access and efficiency. The mini wind tunnels allowed every A&A junior to operate every part of the experiment. With the 3X3 wind tunnel, not only did each team get limited time as Colin mentioned, but most members of each team had a lot of time standing around watching others do the hands-on part of the experiments. Now that the groups are smaller, more of the team is actively involved in the process.

The mini size also allows quick and easy swap of experiments. With the 3x3, it would take a day or two of work by multiple GSAs to swap the experiments. The juniors would not be involved with the test setups which is a critical part of learning aerodynamics and wind tunnel testing!

What did your team learn this first year using the mini wind-tunnels? What are you excited about for next year?

Professor Alvar Saenz Otero: We were happy to have four tunnels set up in our Junior Lab. Each team of four students was able to have three two-hour sessions with their own tunnel, and, ultimately, every team collected data from their tunnel, which was our primary objective. Not only that, our first try at having each team use a custom airfoil was quite successful.

But even with the extra time and ease of use, data were still elusive. We learned that our students can and are ready to choose their custom airfoil earlier in the quarter, which will give us more time to manufacture them. We will also upgrade the balance in the tunnels. And lastly, we still need to find a way to get a full range of Reynolds numbers... but that's what engineering is about!