Amy Sprague

May 17, 2019

"When KWT was built, it was state of the art, but now everyone wants bigger and faster performance, and we couldn’t deliver for some customers or even for some of our own research. We’re now making it possible for customers to test more technologies and different kinds of models.”

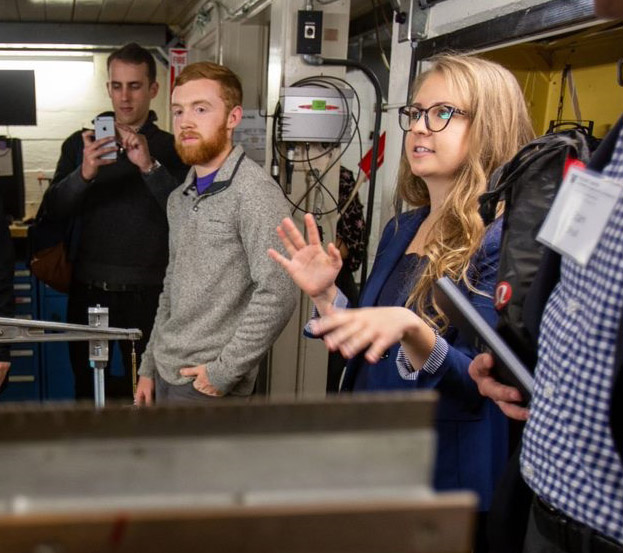

Hannah Stevens gives a tour of the Kirsten Wind Tunnel.

A&A student Hannah Stevens knows quite a bit about wind tunnel research. She has been a researcher with the UW Aircraft Icing & Aerodynamics Research Group (AIARG) for two years, working on printing 3D models of ice to attach to wing models for wind tunnel testing. She is also a senior crew member at the Kirsten Wind Tunnel (KWT). These two roles gives her a specialized perspective on both the advantages and challenges of using the KWT for research.

The work of AIARG, led by Engineering Dean Michael Bragg, includes a series of ice accretion studies funded by the Federal Aviation Administration (FAA), NASA and other industry partners. These studies test how wings perform under icing conditions.

While these UW icing studies are built around wind tunnel testing, Stevens notes that much of this experimental research has been performed in other national and international wind tunnels due to KWT limitations.

A&A Professor Christopher Lum explains, “We haven’t been able to test large wing models in our own wind tunnel, which has increased the cost of our research by sending us to other tunnels, in particular one in France. This limitation creates inefficiencies and expenses not only for us, but for commercial clients that we have in our backyard, like Boeing.”

The ice accretion testing involves printing 3D CAD models of ice that NASA has developed from their own refrigerated wind tunnels. The models can simulate the ice in non-refrigerated tunnels like the KWT.

This limitation is about to be lifted. Now, with funding from Boeing and the Joint Center on Aerospace Technology and Innovation (JCATI) focused on these icing studies, A&A will be improving KWT capabilities by improving the main external balance and installing an upgraded side wall balance that will be able to handle bigger models and bigger loads.

Continues Lum, “When KWT was built, it was state of the art, but now everyone wants bigger and faster performance, and we couldn’t deliver for some customers or even for some of our own research. We’re now making it possible for customers to test more technologies and different kinds of models.”

These upgrades, while funded to support the UW ice accretion research, will benefit all clients and studies requiring more robust balances for bigger models. Stevens notes that the KWT will now offer a responsive flexibility. She explains, “We are working on a heavy high-lift wing model for testing that will require tweaks to the balance that will have to return to an original configuration for other clients testing lighter models, such as unmanned aerial vehicles.”

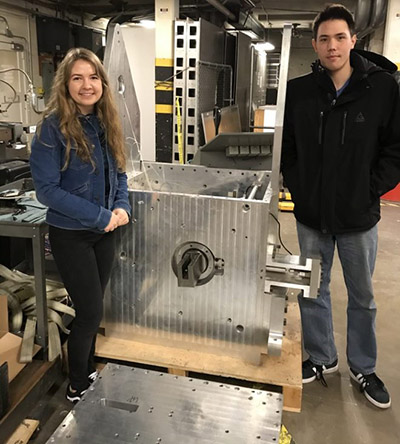

Hannah Stevens and Kevin Ho with the side wall balance that will be tested, adjusted and installed in the wind tunnel.

A&A recent grad Kevin Ho was hired as a research technologist to lead the upgrading of the design and manufacturing of the side wall balance. Explains Ho, “This balance, in particular, will allow for testing bigger 3D wing models at higher testing resolutions. We’re thinking of the future of the models that will come here. We’re not talking about just accommodating a few hundred pounds of model-generated aerodynamic loads, but a few thousand pounds.”

The FAA’s interest in funding the UW ice accretion research is to ultimately create a certified test for icing that can bypass the rarer and more expensive refrigerated tunnels, which is currently an important step in wing design. Advancing this UW research would open up the capabilities of most wind tunnels and reduce the time and cost needed to certify aircraft without compromising safety.

Says Stevens, “You have to keep updating to stay relevant, and these upgrades will keep us in the game. Over the last few years, we have tested lots of unmanned aerial vehicles. We can still work with them, but now we can attend to the high lift customers and the icing research. Plus it benefits the student crew because we get more exposure to another part of the industry.”